Related Information for dongguan factory manufacturer customized all style silicone rubber product:

We can offer our customer OEM/ODM service,

OEM :customer provides 3D drawing, firstly we shall open sample mold (lead time :8~15days);if the samples are approved ,the MP mold will be opened (lead time:15~25days).

ODM: customer provide sample or idea, we can design for customer, but this way will have design cost . please kindly take note .

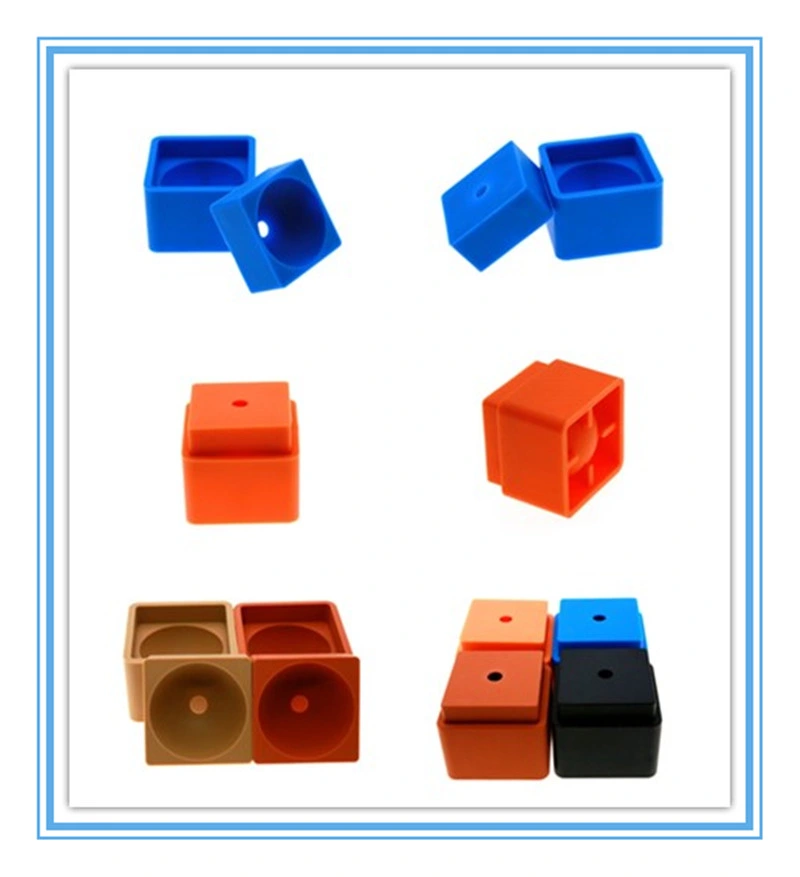

Custom Product Image

the following products only for showing our customization capabilities but not for selling

Products Description

Production Flow

FAQ(Frequently Asked Questions)

Advantages

Company Strength

We can offer our customer OEM/ODM service,

OEM :customer provides 3D drawing, firstly we shall open sample mold (lead time :8~15days);if the samples are approved ,the MP mold will be opened (lead time:15~25days).

ODM: customer provide sample or idea, we can design for customer, but this way will have design cost . please kindly take note .

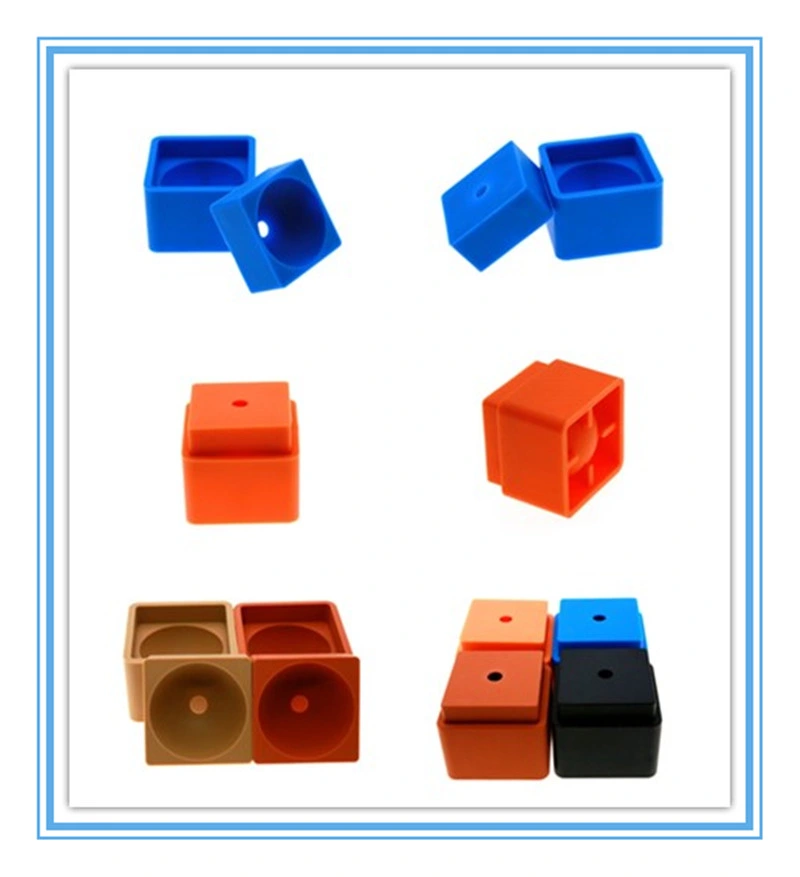

Custom Product Image

the following products only for showing our customization capabilities but not for selling

Products Description

| Part Name | Factory Customized FDA/LFGB Rubber Ice Ball Maker Mold Silicone Ice Tray Molds |

| Service | OEM OR ODM |

| Part Material | Silicone or rubber (NR,NBR,SBR,BR,IR,CR,EPDM,IIR,VTN(FKM),SIR,PU,ACM,CO,etc) |

| Material Hardness | Silicone about 5~90 Shore A; rubber about 10~90 Shore A |

| Size | Customized |

| Shape | Customized |

| Color | Customized according to Pantone colors |

| Appearance | as customer's requirement |

| Drawings | 2D OR 3D acceptable |

| Temperature Resistance | -40~300 degree centigrade |

| Tolerance | 0.05mm |

| Technology | Hot pressing molding or injection Molding |

| Second Processing | Vulcanizing/ Deburring/Silk-screen/Carving/printing |

| Quality control | internal QC control |

| Part Feature | 1.Oxidation , Chemical,oil, acid ,alkali , weather resistance |

| 2. colorful ,Anti-aging,good flexibility, good elasticity | |

| Food grade material | FDA or LFGB |

| MOQ: | Amount : More than USD 500/each part(depends on specific part) |

| Shipping ways | 1. By sea from Shenzhen port or Guangzhou port. 2. By express: DHL/UPS/FEDEX ,etc 3. By air |

| Package | Normally PE bag+carton or customized as customer's request |

| Trade Term | Ex-works; FOB Shenzhen/Guangzhou ; CIF |

| Payment Term | Sample mold: 100% prepaid,MP Mould: 50% deposit by T/T in advance, balance 50% paid after samples approval |

| Goods: 50% deposit, 50% before shipment | |

| T/T, L/C, Western Union, PAYPAL | |

| Lead time | 5~10 days for first article,10~25 days for MP parts (depends on part structure ) |

| Specification | Confirm to ISO-9001 and ROHS Directive Compliant Green Products |

| Application field | 1. Electron components |

| 2. Medical equipment | |

| 3. Home appliance | |

| 4. Mechanical equipment | |

| 5. Office facilities | |

| 6. Aviation | |

| 7. Construction | |

| 8. Automobile |

Production Flow

FAQ(Frequently Asked Questions)

| 1.Why does our customer choose Guanghong silicon rubber company? |

| With 20 years experience, we are the one of the earliest factories which produce silicone rubber parts in China. Have strict process to control the quality and time to produce, which can offer you high quality and punctual delivery time.Get the consistent approval and good reputation from our customers. We have cooperated with many clients from more than 70 countries for many years . |

| 2.With what material ? |

| Our raw materials are imported from France,Japan,Vietnam,Thailand,Indonesia. Mainly Silicone,NR, NBR,SBR,BR,IR,CR,EPDM,IIR,VTN(FKM),SIR,PU,ACM,CO etc... We can offer rubber part according to customer's functional request. |

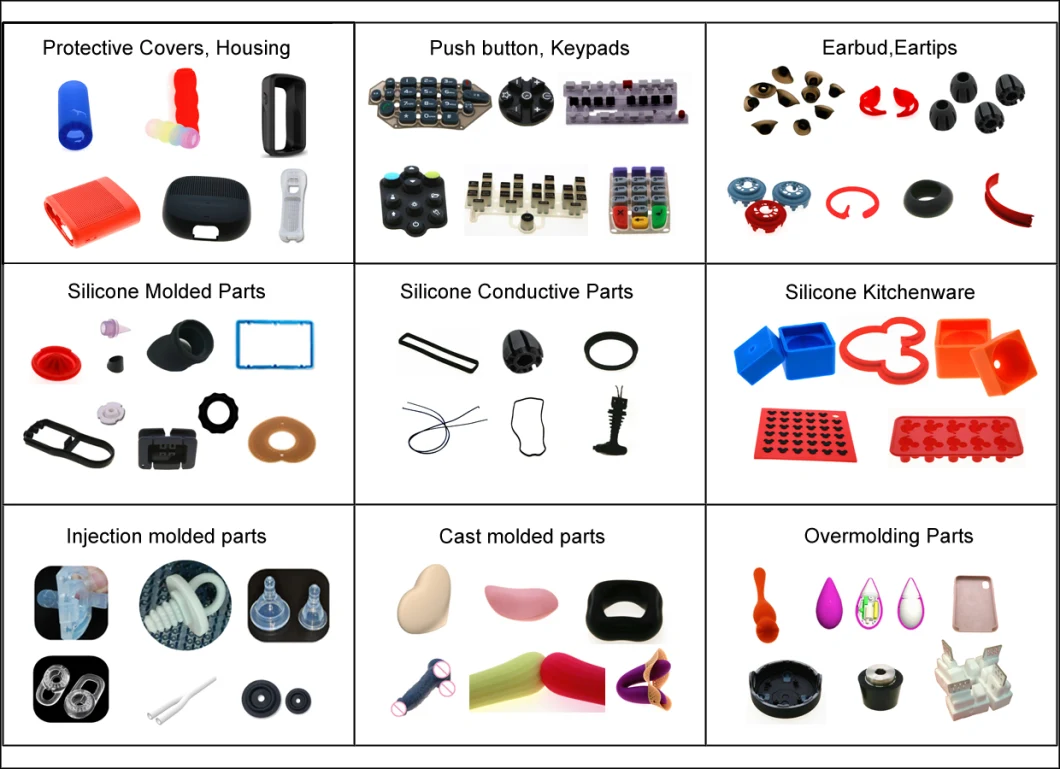

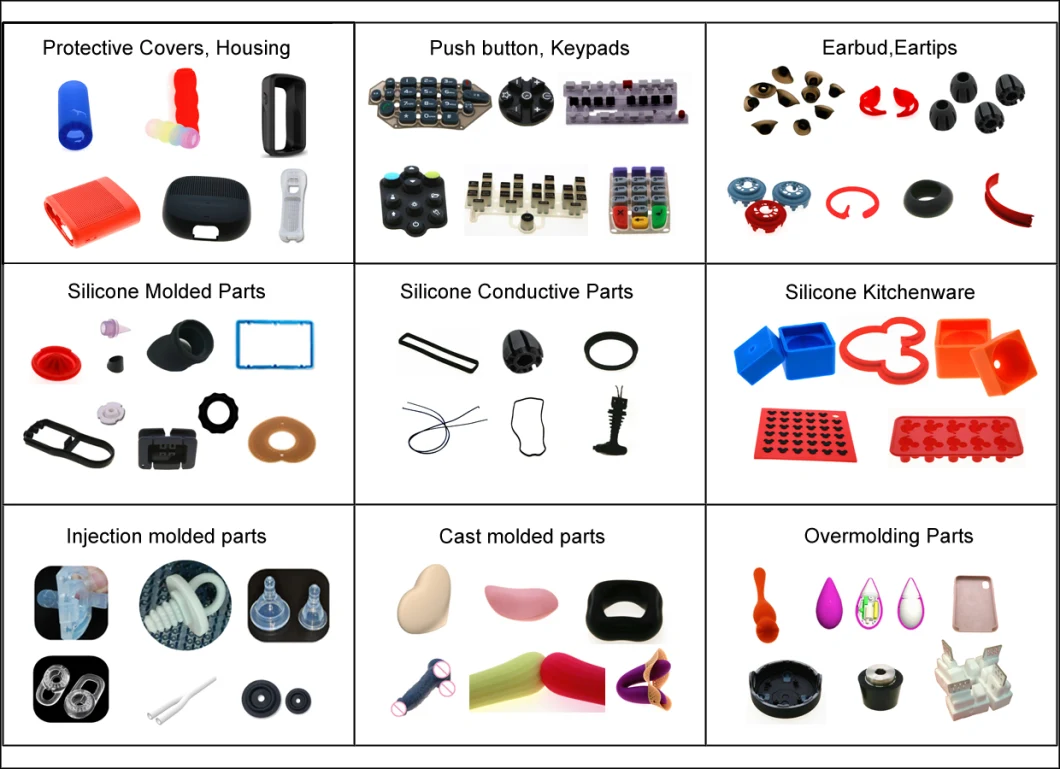

| 3.What are our main products? |

| Our products are customized, main products are the following: 1)Mobile communication and multimedia peripheries(silicon ear bud,loudspeaker,ear hook,silicon wire manager,earphone headband etc). 2)Silione protective case( silicon phone case,silicon handle case. silicone protective case,remote controller case). 3)Kitchenware&bathware&housewares(cup cover,fried egg circle,ice cube,pot mat,ovenware). 4)Sealing rubber,shock,shock absorb rubber,rubber&metal combinations(seal ring,O ring,oil sealing ring. 5)Keypads(single keypad,button for electronic organ,button for electronic dictionary,remote keypad etc). |

| 4.What kind of payment term we accept? |

| 1) Paypal Less than USD1000. 2) T/T More than USD1000 ( please choose business account). Mould: 50% deposit , balance 50% paid after first samples coming out. Goods: 50% deposit, 50% before shipment. |

| 5.What's the MOQ for part? |

| As normal part , over 1000 USD,Others will be specified on the quote. |

| 6.What's the service we offer? |

| 1) OEM service : customer provides 2D & 3D drawing , we open the mold and make parts for customer. Firstly we shall open sample mold. (lead time :8~15days),if the samples are approved ,the MP mold (lead time:15~25days) will be opened. 2) ODM service : customer provide sample or idea, we can design for customer. |

| 7. What certificates do we have ? |

| ISO 9001:2008; ISO14001:2004, TS16949; Green Parner |

| 8. What is the color standard we are using? |

| Pantone color and RAL color or color chip. |

| 9. What information we need for accurate quote? |

| 1) 2D(e.g : jpg. pdf,dwg. dxf. file) or 3D drawing (e.g:igs.stp.prt.file) 2) order quantity 3) material/hardness of material/ color /property 4) application 5) operating environment. 6) Silk printing drawing/second processing if need |

| 10. What's your terms of delivery? |

| EXW, FOB,CIF , Door to Door are availabe |

Advantages

| Our Advantages: |

| 1. With 20 years experience, we are the one of the earliest factories which produce silicone rubber parts in China, have strict process to control the quality and time to produce, which can offer you high quality and punctual delivery time ,More than 60 lines for production to make sure the prompt leadtime for 100% customer satisfaction guaranteed |

| 2. We are the factory to make mold and molded parts, provide customer one-stop service from mould design -- 3D drawing confirmed-- tooling making--MP -- Second processing -- appearance treatment -- packaging--Outgoing. ,which help our customer to save time & money. |

| 3 We provide customers with engineering and technical design support in mold making and product design, Our sale & engineer teams are flexible and friendly. |

| 4. We can perform secondary processing, such as assembly, silk printing, spraying , PU coating ,laser etching when needed. |

| 5. Our factory is currently with 60 molding machines ranging from 100 to 400 tons. |

| 6. We have gained great reputaton and trust from our customers. |

| 7. Unbeatable Prices we continuously strive to find ways of reducing our production costs, and passing the saving cost over to you. |

Company Strength