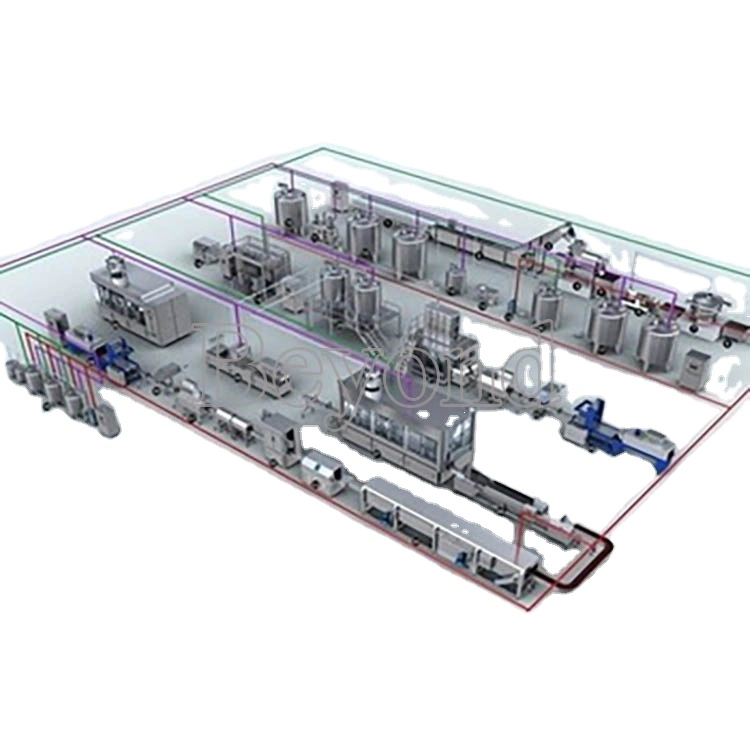

Ice cream processing line

DESCRIPTION

-Formulation:

The ingredients used in ice cream production are: fat;milk solids-non-fat (MSNF);sugar/non-sugar sweetener;emulsifiers/stabilisers;flavouring agents;colouring agents.

-Weighing, measuring and mixing:

Generally speaking, all dry ingredients are weighed, whereas liquid ingredients can be either weighed or proportioned by volumetric meters.

-Homogenisation and pasteurisation:

The ice cream mix flows through a filter to a balance tank and is pumped from there to a plate heat exchanger where it is preheated to 73 - 75deg for homogenisation at 140 - 200 bar, the mix is pasteurised at 83 - 85deg for about 15 seconds then cooled down to 5deg and transferred to an ageing tank.

-Ageing:

The mix must be aged for at least 4 hours at a temperature between 2 to 5degc with continuous gentle agitation. Ageing allows time for the stabiliser to take effect and the fat to crystallise.

-Continuous freezing:

•to whip a controlled amount of air into the mix;

•to freeze the water content in the mix to a large number of small ice crystals.

-Filling in cups, cones and containers;

-Extrusion of sticks and stickless products;

-Moulding of bars

-Wrapping and packaging

-Hardening and cold storage

equipment list for 500L/H mini ice cream processing machine | |||

no. | name | size | main technology parameter |

1 | high speed mixing tank | v=300l | sus304, single layer, high speed mixer 2900rpm, full open removable cover, breath valve, digital thermometer, adjustable legs, sample valve |

2 | centrifugal pump | q=5t/h | sus304,pump head 24m,hard alloy mechanical seal |

3 | tub filter | q=3t/h | sus304,100 mesh |

4 | high pressure homogenizer | q=500l/h | sus304,25mpa |

5 | plate exchanger | q=500l/h | sus304 |

6 | ice cream aging tank | v=500l | sus304 stainless steel,heat insulated,heating or cooling jacket,top off-center vertical agitator,conical head,airtight manhole, breather valve,digital readout thermometer,supporters with adjustable feet |

7 | centrifugal pump | q=5t/h | sus304,pump lift 24m,hard alloy mechanical seal,inner shell bright-polished |

8 | ice cream freezer machine | q=500l/h | sus304,include refrigeration system |

9 | ice cream filling machine | q=500l/h | sus304,roll icecream filling machine |

10 | cip system | q=10t/h | sus304,0.5tx3 |

11 | cip return pump | q=10t/h | sus304,pump head 20m,hard alloy mechanical seal |

12 | boiler | q=500l/h | sus304,electric heating type |

13 | refrigerator |

| air-cooled compressor,with fron as chilling medium,20000kcal |

14 | container for glycol water | v=500l | sus304 stainless steel material,pu heat insulation,thermometer,adjustable feet |

15 | centrifugal pump | q=3t/h | sus304,pump head 24m,hard alloy mechanical seal |

16 | instant cool room | v=25m3 | cool with freon,working at -28°C |

17 | electrical control pannel |

| control all the machines of the mini unit |

18 | fittings and valves |

| juice pipe,glycol pipe,freon pipe |

Condition: New

Brand name: Shanghai Beyond;

Type: whole processing Line/turnkey project/fruit and vegetables processing/dairy processing/beverage processing

Voltage: 220v/380v

Power(W): 100-200kw

Weight: Different size different weight/customized

Dimension(L*W*H): Different size different dimension/customized

Certification: CE&ISO

Warranty: 12 months/1 year

After-sales Service Provided: Engineers available to service machinery overseas

Main material: SUS304 or SUS316

Control type: automatic, semi-automatic

energy consumption: Low consumption with high efficiency

capacity: 500-10000L/H-customized

installation period: 1-3months

Period time: 30 days-120 days

Cups material: pouches, paper box, glass bottle, pet bottle, glass bottleProduct storage condition: room temperature; low temperature;

Related machinery of dairy(cheese, butter, milk, yoghurt,cream) processing line

Large outdoor storage tank, agitator tank, jacket tank, ferment growing tank, emulsification tank, milk weighing, milk receiving/collecting, extracting, pasteurizer yoghurt, UHT, HTST pasteurizer, plate pasteurizer, tubular UHT sterilizer, spraying type pasteurization, cooling tunnel, bottle tilting sterilization chain, CIP cleaning system, full-auto CIP, semi-auto CIP, evaporator, curd cutting, whey draining, cheese making, scalding/stretching/molding, cheese vat, mozzarella cheese, cheddar cheese, blending system, pre-pasteurization, cream separator system, powder melting, dissolving system, homogenizer system, turn-key project.